“A newly developed and patented fish handling system for cleaner fish and wrasse has made life easier for aquaculture farmers”, says Stefan Paulsen of Vøatec AS.

Filtering out cleaner fish has been a major challenge for the industry, and recent tightening of regulations and requirements by the Norwegian Food Safety Authority has led several fish farmers to abandon the use of cleaner fish. Nevertheless, many fish farmers experience good preventive effects and prefer to continue with cleaner fish

Lerøy Aurora is among them and challenged Vøatec to invent a system that would allow them to efficiently and gently filter out the cleaner fish before the salmon were to be slaughtered or deloused.

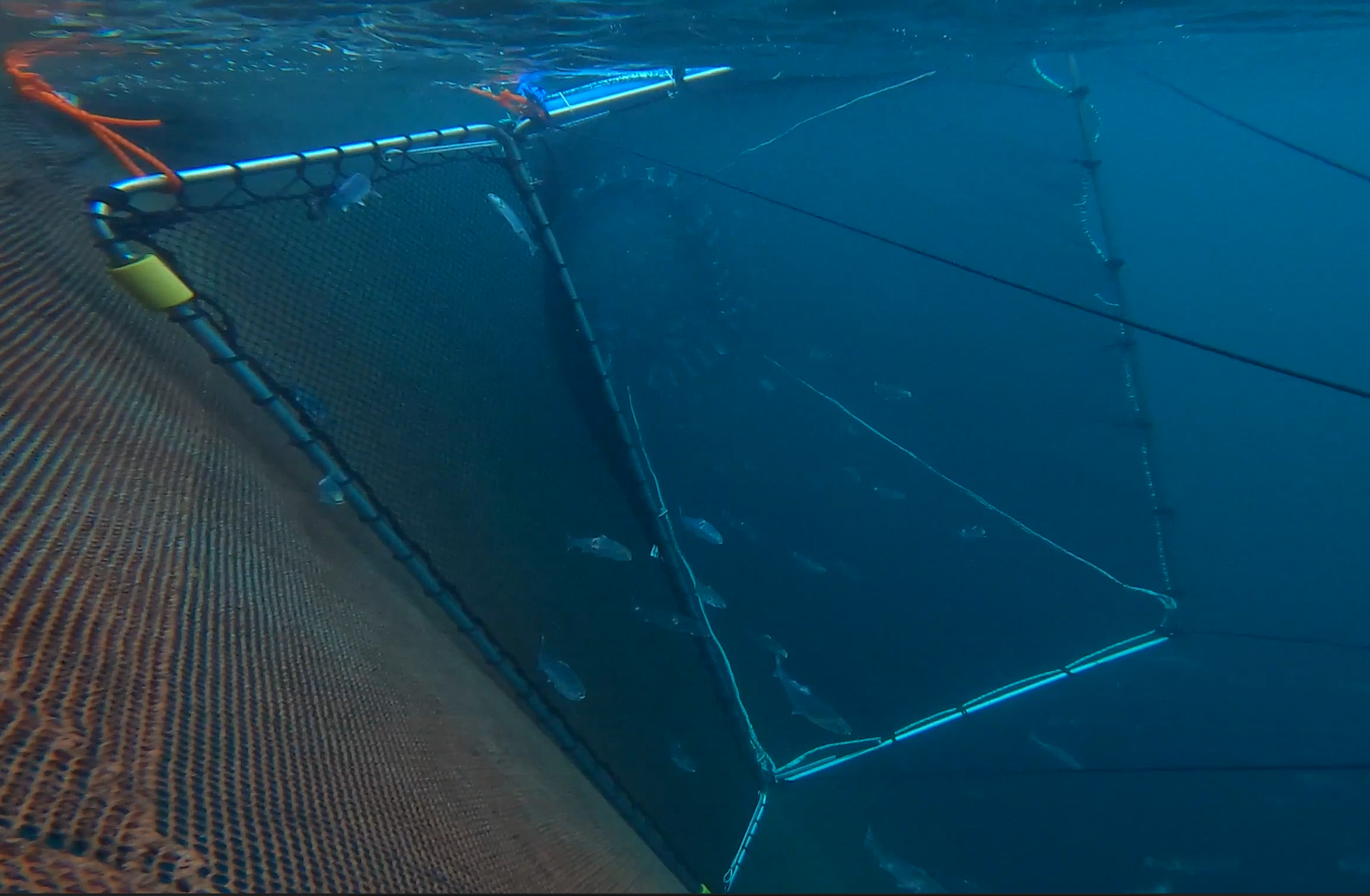

“Through many trials and long days at the pen edge and with different prototypes, it was very rewarding to succeed”, says Paulsen. The cleaner fish are located along the net wall in the upper water layer. We therefore chose to create a trawl with a movable trawl door towards the net wall, which funnels the fish into the trawl bag. The trawl is pulled around the pen using ropes, release hooks, and winches on the boat. Very simple and predictable. After four or five rounds of trawling and a couple of hours of fish counting, the pen was empty of cleaner fish.

More efficient than expected

– We were surprised by how effective it actually was. The amount of fish that accumulated in the trawl led us to completely rethink how the fish should be removed from the pen and onto the boat. To ensure fish welfare and efficient handling on the boat, efforts continued to integrate a dip net onto the trawl and a much larger tank on deck. We have now found good solutions to this,” says Paulsen.

After the commercialization of the fish handling system, SalMar Farming’s cleaner fish coordinator Helge Staven has some experience so far:

– We have tested the trawl on both salmon and lumpfish. There is only positive feedback from the sites that have tried it out. The depletion rate has increased and the time spent has been significantly reduced. Instead of hiring external help, the sites are able to do this job themselves. However, this is also a craft that requires an understanding of how salmon and lumpfish behave in the pen. This is to get the best possible effect from trawling,” says Staven.

A versatile fish handling tool.

Throughout the winter of 2022/2023, many fish farmers struggled with wounded fish and other health-related challenges. Often, large quantities of fish were affected in a short period, and it became challenging to remove this fish from the pen. Paulsen says many local fish farmers in the Senja region got in touch.

– Obviously, when faced with a difficult situation with a lot of wounded and sick fish, it was worth trying to trawl out this fish with our system. We quickly discovered that wounded and stunned fish were moving out of the shoal and towards the net wall where the trawl passes. After a few rounds of trawling, and removal of several thousand fish, the result was very good. I’ve heard that several customers have had deviations closed by the Food Safety Authority, which is very good. Experience shows that if the fish can be filtered out with a dip net, it can be trawled out. However, the trawl has a completely different range than a net and can catch fish that would otherwise not be possible. Preventing infection is important, which means being able to remove the sick fish quickly. We believe that this system will become mainstream fish handling equipment in the future, as well as for emergency preparedness.

Filtering out wounded fish. Photo: Vøatec AS

Senja-based supplier to the entire coast

Vøatec AS is based in Finnsnes in Senja, one of Norway’s largest seafood municipalities. Behind the company are people with extensive experience in the industry: Odd-Arne Korneliussen, Torje Johannessen and Stefan Paulsen. Proximity to the industry has been crucial for success.

– We are a small and young startup company focusing on developing new and better solutions for a growing industry. We are entirely dependent on being able to test what we do at the pen and are grateful to have local fish farmers who allow us to do so. “Now we’re gearing up for growth, but we’ll continue to work on several other exciting development projects”, says Paulsen.

Vøatec has delivered the fish handling equipment to fish farmers from Austevoll in the south to Kirkenes in the north of Norway. Now they hope that more aquaculture companies discover their product, also internationally.

Early phase: Hectic production facilities in Finnsnes. Photo: Vøatec AS.